A.

BAHAN

DAN ALAT YANG DIPERLUKAN

|

No

|

BAHAN

|

jml

|

Perkiraan

Harga (Rp)

|

|

1

|

Kit Smart Chasis 2WD Robot Car

|

1

|

|

|

2

|

Arduino Uno

|

1

|

|

|

3

|

Sensor TCRT5000 5 channel

|

1

|

|

|

4

|

Arduino Protoshield

|

1

|

|

|

5

|

Holder Battery 18650 2 slot

|

1

|

|

|

6

|

Baterai Lithium 18650 3,7 Volt

|

2

|

|

|

7

|

Driver Motor DC L298N

|

1

|

|

|

8

|

Spacer dan Bracket sensor

|

1

|

|

|

9

|

Kabel Jumper

|

1

|

|

|

10

|

Saklar

|

1

|

|

|

Total Rp.

|

|

B. TOPOLOGI ROBOT LINE FOLLOWER (khusus garis hitam menggunakan selotip)

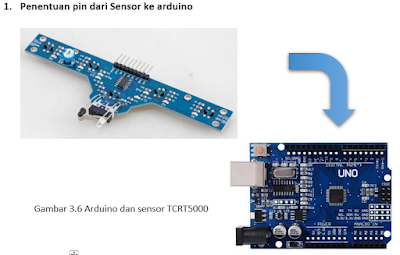

C. PENENTUAN LOKASI PIN UNTUK SENSOR DAN DRIVER

|

No.

|

Sensor

TCRT5000 5 channel

|

Arduino UNO

|

|

1

|

VCC

|

5V

|

|

2

|

GND

|

GND

|

|

3

|

S1

|

A0

|

|

4

|

S2

|

A1

|

|

5

|

S3

|

A2

|

|

6

|

S4

|

A3

|

|

7

|

S5

|

A4

|

|

No.

|

Driver

Motor L298N

|

Arduino

UNO

|

|

1

|

ENA

|

10

|

|

2

|

IN1

|

9

|

|

3

|

IN2

|

8

|

|

4

|

IN3

|

5

|

|

5

|

IN4

|

4

|

|

6

|

ENB

|

3

|

|

7

|

Power 12V

|

Vin

|

|

8

|

Power GND

|

GND

|

D. SKETCH PENGUJIAN FUNGSI UTAMA ROBOT BERODA

Dalam pengujian ini diharapkan untuk mengetahui fungsi dasar robot beroda yang meliputi fungsi sensor garis, fungsi robot lurus, fungsi lurus/mundur/belok. Untuk fungsi sensor garis yang diuji ke lintasan bergaris hitam, nilai yang keluar dari sensor ditayangkan di Serial Monitor pada software Arduino IDE sebagai dasar untuk mengetahui sensor apa yang merespon garis.

1. SKETCH UJI SENSOR GARIS (5 BUAH SENSOR)

SKETCH YANG PERLU DIKETIK:

// Inisialisasi Sensor TCRT5000 5 channel

int sensor1 = A0; // Sensor paling kiri S1 ke A0

int sensor2 = A1; // S2 ke A1

int sensor3 = A2; // S3 ke A2

int sensor4 = A3; // S4 ke A3

int sensor5 = A4; // sensor paling kanan S5 ke A4

// Inisialisasi nilai sensor

int sensor[5] = {0, 0, 0, 0, 0}; // susunan nilai sensor dari S1,S2,S3,S4,S5 secara Array

// dan menetapkan nilai awal masing-masing adalah 0

void setup()

{

pinMode(sensor1, INPUT); // S1 sbg input

pinMode(sensor2, INPUT); // S2 sbg input

pinMode(sensor3, INPUT); // S3 sbg input

pinMode(sensor4, INPUT); // S4 sbg input

pinMode(sensor5, INPUT); // S5 sbg input

Serial.begin(9600);//setting serial monitor at a default baund rate of 9600

delay(500);

}

void loop(){ // ketika robot dinyalakan eksekusi perintah berikut

read_sensor_values();

}

void read_sensor_values()

{

sensor[0] = !digitalRead(sensor1);

sensor[1] = !digitalRead(sensor2);

sensor[2] = !digitalRead(sensor3);

sensor[3] = !digitalRead(sensor4);

sensor[4] = !digitalRead(sensor5);

Serial.print(sensor[0]);

Serial.print(sensor[1]);

Serial.print(sensor[2]);

Serial.print(sensor[3]);

Serial.println(sensor[4]);

delay(100);

}

SKETCH YANG PERLU DIKETIK:

// Penetapan Nama Variabel motor dan pin yang ditentukan

int ENA = 10; // pengatur kecepatan motor kiri di pin 10 pwm

int IN1 = 9; //IN1 motor kiri

int IN2 = 8; //IN2 motor kiri

int IN3 = 5; //IN3 motor kanan

int IN4 = 4; //IN4 motor kanan

int ENB = 3; // pengatur kecepatan motor kanan di pin 3 pwm

void setup()

{

pinMode(IN1, OUTPUT); // in1 kiri

pinMode(IN2, OUTPUT); // in2 kiri

pinMode(IN3, OUTPUT); // in3 kanan

pinMode(IN4, OUTPUT); // in4 kanan

pinMode(ENA, OUTPUT); // nilai kecepatan motor kiri

pinMode(ENB, OUTPUT); // nilai kecepatan motor kanan

}

void loop(){

forward(); //MAJU selama 3 detik

delay(3000);

reverse();//MUNDUR selama 3 detik

delay(3000);

right(); //BELOKKANAN selama 2 detik

delay(2000);

left(); //BELOKKIRI selama 2 detik

delay(2000);

stop_bot(); //STOP selama 2 detik

delay(2000);

}

void forward(){

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void reverse(){

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void right(){

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}

void left(){

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void sharpRightTurn(){

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void sharpLeftTurn() {

analogWrite(ENA, 250); //Left Motor Speed

analogWrite(ENB, 250); //Right Motor Speed

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void stop_bot(){

analogWrite(ENA, 0); //Left Motor Speed

analogWrite(ENB, 0); //Right Motor Speed

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}SKETCH YANG PERLU DIKETIK:

// Penetapan Nama Variabel motor dan pin yang ditentukan

int ENA = 10; // pengatur kecepatan motor kiri di pin 5 pwm

int IN1 = 9; //IN1 motor kiri

int IN2 = 8; //IN2 motor kiri

int IN3 = 5; //IN3 motor kanan

int IN4 = 4; //IN4 motor kanan

int ENB = 3; // pengatur kecepatan motor kanan di pin 3 pwm

//inisialisasi penetapan power kecepatan motor

int Speed_Utama = 130; // Speed_Utama bernilai 0 hingga 250

int Speed_Kiri = Speed_Utama; //penentuan kecepatan motor kiri

int Speed_Kanan = Speed_Utama+5; //penentuan kecepatan motor kanan

int left_motor_speed; // membuat variabel kecepatan motor kiri

int right_motor_speed; // membuat variabel kecepatan motor kanan

void setup()

{

pinMode(IN1, OUTPUT); // in1 kiri

pinMode(IN2, OUTPUT); // in2 kiri

pinMode(IN3, OUTPUT); // in3 kanan

pinMode(IN4, OUTPUT); // in4 kanan

pinMode(ENA, OUTPUT); // nilai kecepatan motor kiri

pinMode(ENB, OUTPUT); // nilai kecepatan motor kanan

}

void loop(){

motor_control(); //kendali kecepatan

forward(); //MAJU selama 3 detik

delay(3000);

stop_bot(); //STOP selama 3 detik

delay(3000);

}

void motor_control()

{

int left_motor_speed = Speed_Kiri;

int right_motor_speed = Speed_Kanan;

analogWrite(ENA, left_motor_speed);

analogWrite(ENB, right_motor_speed);

}

void forward(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void reverse(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void right(){

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}

void left(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void sharpRightTurn(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void sharpLeftTurn() {

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void stop_bot(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}E. ROBOT LINE FOLLOWER TYPE BIASA

Robot Line Follower type biasa menggunakan logika untuk menentukan arah robot, gerakannya lambat dan terbata-bata namun dapat kita jadikan indikator keberhasilan gerak robot menyusuri garis sebelum diprogram dengan PID Controller (Proportional, Integral, Derivative).

|

1.

Analisis Gerak Line Follower

jika nilai 1 = KENA GARIS

|

|

No.

|

SENSOR TCRT5000

|

ARAH ROBOT

|

|

S1

|

S2

|

S3

|

S4

|

S5

|

|

1

|

0

|

0

|

1

|

0

|

0

|

LURUS

↑

|

|

2

|

0

|

1

|

1

|

0

|

0

|

LURUS

↑

|

|

3

|

0

|

0

|

1

|

1

|

0

|

LURUS

↑

|

|

4

|

0

|

1

|

1

|

1

|

0

|

LURUS

↑

|

|

5

|

1

|

1

|

1

|

1

|

1

|

STOP

|

|

6

|

0

|

0

|

0

|

0

|

1

|

KE

KIRI←

|

|

7

|

0

|

0

|

0

|

1

|

0

|

KE

KIRI←

|

|

8

|

0

|

0

|

0

|

1

|

1

|

KE

KIRI←

|

|

9

|

0

|

0

|

1

|

1

|

1

|

KE KIRI

90 DERAJAT←

|

|

10

|

1

|

0

|

0

|

0

|

0

|

KE

KANAN→

|

|

11

|

|

1

|

0

|

0

|

0

|

KE

KANAN→

|

|

12

|

1

|

1

|

0

|

0

|

0

|

KE

KANAN→

|

|

13

|

1

|

1

|

1

|

0

|

0

|

KE

KANAN 90 DERAJAT→

|

|

14

|

0

|

0

|

0

|

0

|

0

|

BELOK

KANAN 180 DERAJAT→↓

|

|

|

|

|

|

|

|

|

2.

Analisis Gerak Line Follower

jika nilai 0 = KENA GARIS

|

|

No.

|

SENSOR TCRT5000

|

ARAH ROBOT

|

|

S1

|

S2

|

S3

|

S4

|

S5

|

|

1

|

1

|

1

|

0

|

1

|

1

|

LURUS

↑

|

|

2

|

1

|

0

|

0

|

1

|

1

|

LURUS

↑

|

|

3

|

1

|

1

|

0

|

0

|

1

|

LURUS

↑

|

|

4

|

1

|

0

|

0

|

0

|

1

|

LURUS

↑

|

|

5

|

0

|

0

|

0

|

0

|

0

|

STOP

|

|

6

|

1

|

1

|

1

|

1

|

0

|

KE

KIRI←

|

|

7

|

1

|

1

|

1

|

0

|

1

|

KE

KIRI←

|

|

8

|

1

|

1

|

1

|

0

|

0

|

KE

KIRI←

|

|

9

|

1

|

1

|

0

|

0

|

0

|

KE

KIRI 90 DERAJAT←

|

|

10

|

0

|

1

|

1

|

1

|

1

|

KE

KANAN→

|

|

11

|

1

|

0

|

1

|

1

|

1

|

KE

KANAN→

|

|

12

|

0

|

0

|

1

|

1

|

1

|

KE

KANAN→

|

|

13

|

0

|

0

|

0

|

1

|

1

|

KE

KANAN 90 DERAJAT→

|

|

14

|

1

|

1

|

1

|

1

|

1

|

BELOK

KANAN 180 DERAJAT→↓

|

F. ROBOT LINE FOLLOWER KENDALI BIASA (Status: Berhasil)

Sebelum menggunakan sketch robot line follower biasa dan PID maka sebaiknya robot di uji lurus terlebih dahulu.

SKETCH ROBOT LINE FOLLOWER BIASA

// line follower biasa 5 sensor

// sketch khusus prototype R-Madina-01

//12 maret 2021

//SMK TERPADU MADINA

// sensor line follower type TCRT5000 5channel

// arduino uno dan protoshield

// modul L298N

#define enA 10

#define in1 9

#define in2 8

#define in3 5

#define in4 4

#define enB 3

// sensor TCRT5000 5channel, VCC ke 5V, GND ke GND

#define left A0 // S1 ke A0

#define mid1 A1 // S2 ke A1

#define mid2 A2 // S3 ke A2

#define mid3 A3 // S4 ke A3

#define right A4 // S5 ke A4

int speed_maju=120;

int a;

int b;

int c;

int d;

int e;

void setup() {

pinMode(enA, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

pinMode(left, INPUT);

pinMode(mid1, INPUT);

pinMode(mid2, INPUT);

pinMode(mid3, INPUT);

pinMode (right, INPUT);

Serial.begin(9600);

}

void loop() {

int a=digitalRead(left);

int b=digitalRead(mid1);

int c=digitalRead(mid2);

int d=digitalRead(mid3);

int e=digitalRead(right);

Serial.print(a);

Serial.print(" : ");

Serial.print(b);

Serial.print(" : ");

Serial.print(c);

Serial.print(" : ");

Serial.print(d);

Serial.print(" : ");

Serial.println(e);

// gerakan robot

if((a==1)&&(b==1)&&(c==0)&&(d==1)&&(e==1)){

gerak_maju();

} //11011 gerak maju

else if((a==1)&&(b==1)&&(c==1)&&(d==1)&&(e==1)){

gerak_maju();

} // 11111 gerak maju

else if((a==1)&&(b==0)&&(c==0)&&(d==1)&&(e==1)){

gerak_maju();

} // 10011 gerak maju

else if((a==1)&&(b==1)&&(c==0)&&(d==0)&&(e==1)){

gerak_maju();

} // 11001 gerak maju

else if((a==1)&&(b==1)&&(c==1)&&(d==1)&&(e==0)){

belok_kiri();

delay(50);

motor_stop();

delay(250);

belok_kiri();

} //11110 belok kiri

else if((a==1)&&(b==1)&&(c==1)&&(d==0)&&(e==1)){

belok_kiri();

delay(50);

motor_stop();

delay(250);

belok_kiri();

} // 11101 belok kiri

else if((a==1)&&(b==1)&&(c==1)&&(d==0)&&(e==0)){

belok_kiri();

delay(50);

motor_stop();

delay(250);

belok_kiri();

} // 11100 belok kiri

else if((a==1)&&(b==1)&&(c==0)&&(d==0)&&(e==0)){

belok_kiri();

delay(50);

motor_stop();

delay(250);

belok_kiri();

} // 11000 belok kiri 90 derajat

else if((a==0)&&(b==1)&&(c==1)&&(d==1)&&(e==1)){

belok_kanan();

delay(50);

motor_stop();

delay(250);

belok_kanan();

} // 01111 belok kanan

else if((a==0)&&(b==0)&&(c==1)&&(d==1)&&(e==1)){

belok_kanan();

delay(50);

motor_stop();

delay(250);

belok_kanan();

} // 00111 belok kanan

else if((a==1)&&(b==0)&&(c==1)&&(d==1)&&(e==1)){

belok_kanan();

delay(50);

motor_stop();

delay(250);

belok_kanan();

} // 10111 belok kanan

else if((a==0)&&(b==0)&&(c==0)&&(d==1)&&(e==1)){

belok_kanan();

delay(50);

motor_stop();

delay(250);

belok_kanan();

} // 00011 belok kanan

else if((a==0)&&(b==0)&&(c==0)&&(d==0)&&(e==0)){

motor_stop();

} //00000 stop

}

void gerak_maju(){

analogWrite (enA, speed_maju);

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

analogWrite (enB, speed_maju);

} // fungsi robot berjalan maju

void belok_kanan(){

analogWrite (enA, 200);

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

analogWrite (enB, 200);

} // fungsi robot berbelok kanan

void belok_kiri(){

analogWrite (enA, 200);

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

analogWrite (enB, 200);

} // fungsi robot berbelok kiri

void motor_stop(){

analogWrite (enA, 0);

analogWrite (enB, 0);

} // fungsi robot berhenti

G. ROBOT LINE FOLLOWER DENGAN KENDALI PID (PROPORTIONAL, INTEGRAL,DERIVATIVE) (status:berhasil)

|

Analisis Gerak Line Follower PID jika nilai 1 = KENA GARIS

|

|

|

|

No.

|

SENSOR TCRT5000

|

ARAH ROBOT

|

|

S1

|

S2

|

S3

|

S4

|

S5

|

|

1

|

0

|

0

|

0

|

0

|

0

|

error = 5

|

|

2

|

1

|

0

|

0

|

0

|

0

|

error = 4

|

|

3

|

1

|

1

|

0

|

0

|

0

|

error = 3

|

|

4

|

0

|

1

|

0

|

0

|

0

|

error = 2

|

|

5

|

0

|

1

|

1

|

0

|

0

|

error = 1

|

|

6

|

0

|

0

|

1

|

0

|

0

|

error = 0

|

|

7

|

0

|

0

|

1

|

1

|

0

|

error = -1

|

|

8

|

0

|

0

|

0

|

1

|

0

|

error = -2

|

|

9

|

0

|

0

|

0

|

1

|

1

|

error = -3

|

|

10

|

0

|

0

|

0

|

0

|

1

|

error = -4

|

|

11

|

0

|

0

|

0

|

0

|

0

|

error = -5

|

|

12

|

1

|

1

|

1

|

0

|

0

|

error = 100

|

|

13

|

0

|

0

|

1

|

1

|

1

|

error = 101

|

|

14

|

1

|

1

|

1

|

1

|

1

|

error = 103

|

SKETCH ROBOT LINE FOLLOWER PENGENDALI PID

// Inisialisasi Sensor TCRT5000 5 channel

int sensor1 = A0; // Sensor paling kiri S1 ke A0

int sensor2 = A1; // S2 ke A1

int sensor3 = A2; // S3 ke A2

int sensor4 = A3; // S4 ke A3

int sensor5 = A4; // sensor paling kanan S5 ke A4

// Inisialisasi nilai sensor

int sensor[5] = {0, 0, 0, 0, 0}; // susunan nilai sensor dari S1,S2,S3,S4,S5 secara Array

// dan menetapkan nilai awal masing-masing adalah 0

// Penetapan Nama Variabel motor dan pin yang ditentukan

int ENA = 10; // pengatur kecepatan motor kiri di pin 10 pwm

int IN1 = 9; //IN1 motor kiri

int IN2 = 8; //IN2 motor kiri

int IN3 = 5; //IN3 motor kanan

int IN4 = 4; //IN4 motor kanan

int ENB = 3; // pengatur kecepatan motor kanan di pin 3 pwm

//inisialisasi penetapan power kecepatan motor

int Speed_Utama = 130; // Speed_Utama bernilai 0 hingga 250

int Speed_Kiri = Speed_Utama; //penentuan kecepatan motor kiri

int Speed_Kanan = Speed_Utama+5; //penentuan kecepatan motor kanan

int left_motor_speed; // membuat variabel kecepatan motor kiri

int right_motor_speed; // membuat variabel kecepatan motor kanan

// menambahkan led penanda (optional)

int ledPin1 = 11; // led1 di pin 11

int ledPin2 = 12; // led2 di pin 12

// konstanta proporsional, integral, dan derivatif. disini nilai disesuaikan

float Kp = 39;

float Ki = 13 ;

float Kd = 30 ;

float error = 0, P = 0, I = 0, D = 0, PID_value = 0; // penetapan nilai awal = 0

float previous_error = 0, previous_I = 0;

int flag = 0;

void setup()

{

pinMode(sensor1, INPUT); // S1 sbg input

pinMode(sensor2, INPUT); // S2 sbg input

pinMode(sensor3, INPUT); // S3 sbg input

pinMode(sensor4, INPUT); // S4 sbg input

pinMode(sensor5, INPUT); // S5 sbg input

pinMode(IN1, OUTPUT); // in1 kiri

pinMode(IN2, OUTPUT); // in2 kiri

pinMode(IN3, OUTPUT); // in3 kanan

pinMode(IN4, OUTPUT); // in4 kanan

pinMode(ENA, OUTPUT); // nilai kecepatan motor kiri

pinMode(ENB, OUTPUT); // nilai kecepatan motor kanan

pinMode(ledPin1, OUTPUT);

pinMode(ledPin2, OUTPUT);

digitalWrite(ledPin1, LOW);

digitalWrite(ledPin2, LOW);

Serial.begin(9600);//setting serial monitor at a default baund rate of 9600

delay(500);

}

void loop(){ // ketika robot dinyalakan eksekusi perintah berikut

read_sensor_values();

calculate_pid();

if (error == 100) {

do {

read_sensor_values();

analogWrite(ENA, left_motor_speed); //Left Motor Speed

analogWrite(ENB, right_motor_speed); //Right Motor Speed

sharpLeftTurn();

} while (error != 0);

} else if (error == 101) {

analogWrite(ENA, left_motor_speed); //Left Motor Speed

analogWrite(ENB, right_motor_speed); //Right Motor Speed

forward();

delay(200);

stop_bot();

}else if (error == 103) {

if (flag == 0) {

analogWrite(ENA, left_motor_speed); //Left Motor Speed

analogWrite(ENB, right_motor_speed); //Right Motor Speed

forward();

delay(200);

stop_bot();

read_sensor_values();

if (error == 103) {

stop_bot();

digitalWrite(ledPin1, HIGH);

digitalWrite(ledPin2, HIGH);

flag = 1;

} else {

analogWrite(ENA, left_motor_speed); //Left Motor Speed

analogWrite(ENB, right_motor_speed); //Right Motor Speed

sharpLeftTurn();

delay(200);

do {

read_sensor_values();

analogWrite(ENA, left_motor_speed); //Left Motor Speed

analogWrite(ENB, right_motor_speed); //Right Motor Speed

sharpLeftTurn();

} while (error != 0);

}

}

} else {

calculate_pid();

motor_control();

forward();

}

}

void read_sensor_values()

{

sensor[0] = !digitalRead(sensor1);

sensor[1] = !digitalRead(sensor2);

sensor[2] = !digitalRead(sensor3);

sensor[3] = !digitalRead(sensor4);

sensor[4] = !digitalRead(sensor5);

//menentukan nilai definisi error dari hasil sensor

if ((sensor[0] == 1) && (sensor[1] == 0) && (sensor[2] == 0) && (sensor[3] == 0)&& (sensor[4] == 0))

error = 4; // 01111 = 10000

else if ((sensor[0] == 1) && (sensor[1] == 1) && (sensor[2] == 0) && (sensor[3] == 0)&& (sensor[4] == 0))

error = 3; // 00111 = 11000

else if ((sensor[0] == 0) && (sensor[1] == 1) && (sensor[2] == 0) && (sensor[3] == 0)&& (sensor[4] == 0))

error = 2; // 10111 = 01000

else if ((sensor[0] == 0) && (sensor[1] == 1) && (sensor[2] == 1) && (sensor[3] == 0)&& (sensor[4] == 0))

error = 1; // 10011 = 01100

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 1) && (sensor[3] == 0)&& (sensor[4] == 0))

error = 0; // 11011 = 00100

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 1) && (sensor[3] == 1)&& (sensor[4] == 0))

error = -1; // 11001 = 00110

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 0) && (sensor[3] == 1)&& (sensor[4] == 0))

error = -2; // 11101 = 00010

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 0) && (sensor[3] == 1)&& (sensor[4] == 1))

error = -3; // 11100 = 00011

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 0) && (sensor[3] == 0)&& (sensor[4] == 1))

error = -4; // 11110 = 00001

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 0) && (sensor[3] == 0)&& (sensor[4] == 0))

if(previous_error==(-4)) {error = -5;} // jika semua sensor mengenai garis putih, jika error sebelumnya -4 maka error = -5

if(previous_error==(4)) {error = 5;} // jika semua sensor mengenai garis putih, jika error sebelumnya 4 maka error = 5

// kondisi khas tertentu

else if ((sensor[0] == 1) && (sensor[1] == 1) && (sensor[2] == 1) && (sensor[3] == 0)&& (sensor[4] == 0)) // Turn robot left side

error = 100; //1110 -00011 = 11100

else if ((sensor[0] == 0) && (sensor[1] == 0) && (sensor[2] == 1) && (sensor[3] == 1)&& (sensor[4] == 1)) // Turn robot right side

error = 101; //0111 -11000 = 00111

else if ((sensor[0] == 1) && (sensor[1] == 1) && (sensor[2] == 1) && (sensor[3] == 1)&& (sensor[4] == 1)) // Turn left side or stop

error = 103; //1111 -00000 = 11111

}

void calculate_pid(){ //perhitungan nilai PID

previous_I = I;

previous_error = error;

P = error;

I = I + previous_I;

D = error - previous_error;

PID_value = (Kp * P) + (Ki * I) + (Kd * D);

}

void motor_control()

{

// Calculating the effective motor speed:

int left_motor_speed = Speed_Utama - PID_value;

int right_motor_speed = Speed_Utama + PID_value;

// The motor speed should not exceed the max PWM value

left_motor_speed = constrain(left_motor_speed, 0, Speed_Kiri);

right_motor_speed = constrain(right_motor_speed, 0, Speed_Kanan);

analogWrite(ENA, left_motor_speed); //kecepatan motor kiri yang sudah dipengaruhi PID

analogWrite(ENB, right_motor_speed); //Kecepatan motor kanan yang sudah dipengaruhi PID

// Menampilkan nilai-nilai di serial monitor

Serial.print("ERROR: ");

Serial.print(error);

Serial.print("PID: ");

Serial.print(PID_value);

Serial.print("KEC KIRI: ");

Serial.print(left_motor_speed);

Serial.print("KEC KANAN: ");

Serial.println(right_motor_speed);

}

void forward(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void reverse(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void right(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}

void left(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void sharpRightTurn(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

}

void sharpLeftTurn() {

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

}

void stop_bot(){

analogWrite(ENA, 0); //Left Motor Speed

analogWrite(ENB, 0); //Right Motor Speed

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

}

|

NO

|

KP

|

KI

|

KD

|

SPEED

|

KETERANGAN

|

|

1

|

39

|

13

|

30

|

130

|

Max speed 250

|

|

2

|

60

|

1

|

160

|

150

|

STABIL

|

|

3

|

80

|

1

|

320

|

250

|

Non stabil

|

|

4

|

|

|

|

|

|

|

5

|

|

|

|

|

|

|

6

|

|

|

|

|

|

|

7

|

|

|

|

|

|

|

8

|

|

|

|

|

|

|

9

|

|

|

|

|

|

|

10

|

|

|

|

|

|

|

11

|

|

|

|

|

|

|

12

|

|

|

|

|

|

|

13

|

|

|

|

|

|

|

14

|

|

|

|

|

|

|

15

|

|

|

|

|

|

|

16

|

|

|

|

|

|

|

17

|

|

|

|

|

|

|

18

|

|

|

|

|

|

|

19

|

|

|

|

|

|

|

20

|

|

|

|

|

|